In the competitive world of cigarette manufacturing, choosing the right plug wrap paper is crucial for optimizing performance and cost-effectiveness. Two popular options in this field are porous and non-porous plug wrap papers. But how do these materials differ, and which one is right for your needs? Let’s explore the differences, unique advantages, and cost implications, with a focus on how Minfeng can provide tailored solutions for your business.

1. Difference between Porous and Non-porous

What is Porous Plug Wrap Paper?

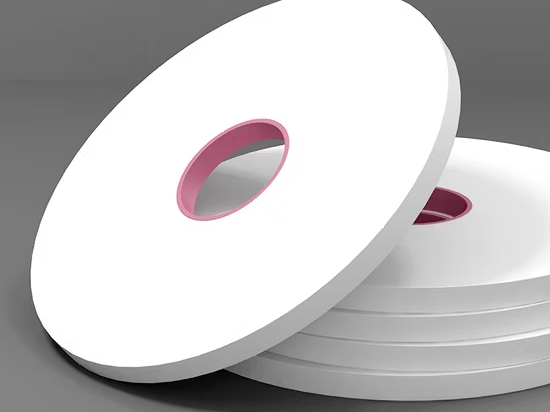

Porous plug wrap paper is designed with tiny holes that allow controlled air permeability.

This paper is widely used in cigarettes to manage the airflow, enhance the smoking experience, and ensure even combustion.

Typically, porous paper is made from high-quality wood pulp combined with advanced manufacturing techniques to achieve precise porosity.

What is Non-Porous Plug Wrap Paper?

Non-porous plug wrap paper, on the other hand, is a solid, impermeable material without air holes.

It provides a tight seal around the cigarette filter, ensuring durability and stability. Non-porous paper is often chosen for its robust structure and ability to maintain its shape during production and usage.

Key Differences Between Them

● Material Composition: Both types are made from premium-grade wood pulp, but porous paper undergoes additional processes to create the small holes that allow airflow.

● Technique: Porous paper requires precision perforation techniques, while non-porous paper focuses on achieving strength and uniformity.

● Functionality: Porous paper controls airflow, making it essential for certain cigarette designs, while non-porous paper provides a stronger barrier, ideal for specific manufacturing needs.

2. Advantages of Using Porous Plug Wrap Paper

Porous plug wrap paper offers several advantages that make it a preferred choice for many manufacturers:

● Improved Airflow Control: The tiny holes allow just the right amount of air to pass through, ensuring an optimal smoking experience.

● Enhanced Combustion: Better airflow contributes to a smoother burn, improving product quality.

● Customization Options: The level of porosity can be tailored to meet specific requirements, providing flexibility for different cigarette types.

● Regulatory Compliance: Many countries mandate the use of porous materials in certain cigarette types to align with ventilation standards.

3. Right Choice Can Optimize Your Budget

Choosing between porous and non-porous plug wrap paper isn’t just about functionality—it’s also about cost performance.

Let’s break it down:

● Material Costs: Porous paper typically involves a slightly higher production cost due to the added perforation process. However, its advantages in airflow and burn control often justify the investment.

● Production Efficiency: Non-porous paper can be more straightforward to manufacture and may reduce initial costs. However, it might not provide the same level of customization or performance for specific cigarette designs.

● Overall Returns: While porous paper may have a higher upfront cost, it can enhance the product’s value and appeal, leading to better sales performance and customer satisfaction.

At Minfeng, we understand the importance of balancing quality and cost. We work closely with our clients to help them choose the right material for their needs, ensuring they achieve maximum returns on their investment.

4. Tailored Solutions for Your Needs

At Minfeng, we pride ourselves on being more than just a supplier—we’re your trusted partner in plug wrap paper solutions.

Here’s how we deliver value to your business:

● Material Selection Expertise: With decades of experience, we guide you in choosing between porous and non-porous plug wrap paper based on your specific requirements and goals.

● Advanced Technical Applications: Our state-of-the-art facilities and innovative techniques ensure that every roll of paper meets the highest standards of quality and consistency.

● Ongoing Support: From initial consultations to post-purchase assistance, we provide comprehensive support to help you maximize the performance of our products.

● Customized Solutions: Whether you need tailored porosity levels or specific dimensions, we offer fully customized solutions to fit your unique needs.

Partnering with Minfeng means you’re not just getting high-quality materials—you’re gaining a collaborative experience that drives your success.

Conclusion

Understanding the differences between porous and non-porous plug wrap papers is key to making an informed decision for your business.

While porous paper excels in airflow control and customization, non-porous paper offers strength and simplicity.

At Minfeng, we’re here to help you navigate these choices and find the perfect solution that aligns with your production goals and budget.

Reach out to Minfeng today to discover how our expertise and premium plug wrap paper products can elevate your business to new heights.